SOK has built quite a reputation for themselves for their 12V 100Ah LiFePO4 battery. Many other companies are building batteries in the same old plastic cases over and over again whereas SOK decided they wanted to be different and built using steel cases and their own in-house BMS.

Recently, Current Connected partnered with SOK to design a new 48V rack-mount battery. Today we’re going to take a look at the battery, run some basic tests, then tear it down and see how it’s built inside. The battery I’ll be testing was sponsored by Current Connected for the purposes of review.

The batteries shipped from Nevada via freight service and arrived in about a week. The freight service called to schedule a delivery time, which was nice as to not have a giant pallet dropped in the driveway randomly that could get rained on. The batteries are enclosed in foam, double-boxed, and strapped down to the pallet nicely. This thing could probably roll over and they would be fine (but let’s not try).

The batteries are built in heavy-duty powder-coated steel cases. These cases are designed to fit a standard 19″ server rack – it’s become a popular formfactor in recent months. The case are of the 3U formfactor measuring 17.5″ wide (without ears), 7″ high, and 18″ in depth (not including handles). They weigh in right around 100lbs, so you’ll need a good set of shelves to support the weight, or they sell a specially-designed rack for them.

The front of the battery features a pair of each positive and negative heavy-duty terminals with a Chint 125A circuit breaker. The BMS-related components include an LCD screen showing temperatures, voltages of each cell, state of charge information, and more. We also have a series of RJ45 and RJ11 ports for RS232, RS485, and CAN communication to other batteries, inverters, and even your computer, which they provide software you can use to view technical details of the battery.

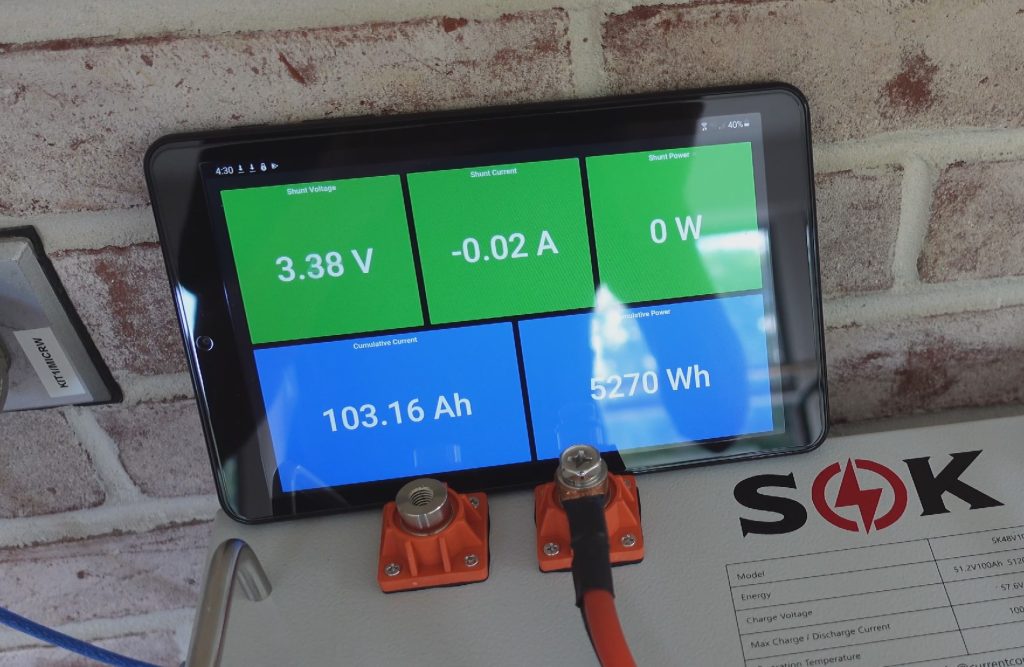

For the capacity test, I ran an inverter charging another battery that put a load of approximately 1.3kW on the battery. This load remained constant throughout the duration of the test and continued until the BMS of the battery shut off the discharge once it detected the battery was depleted. Our measured capacity was 103Ah – perfect!

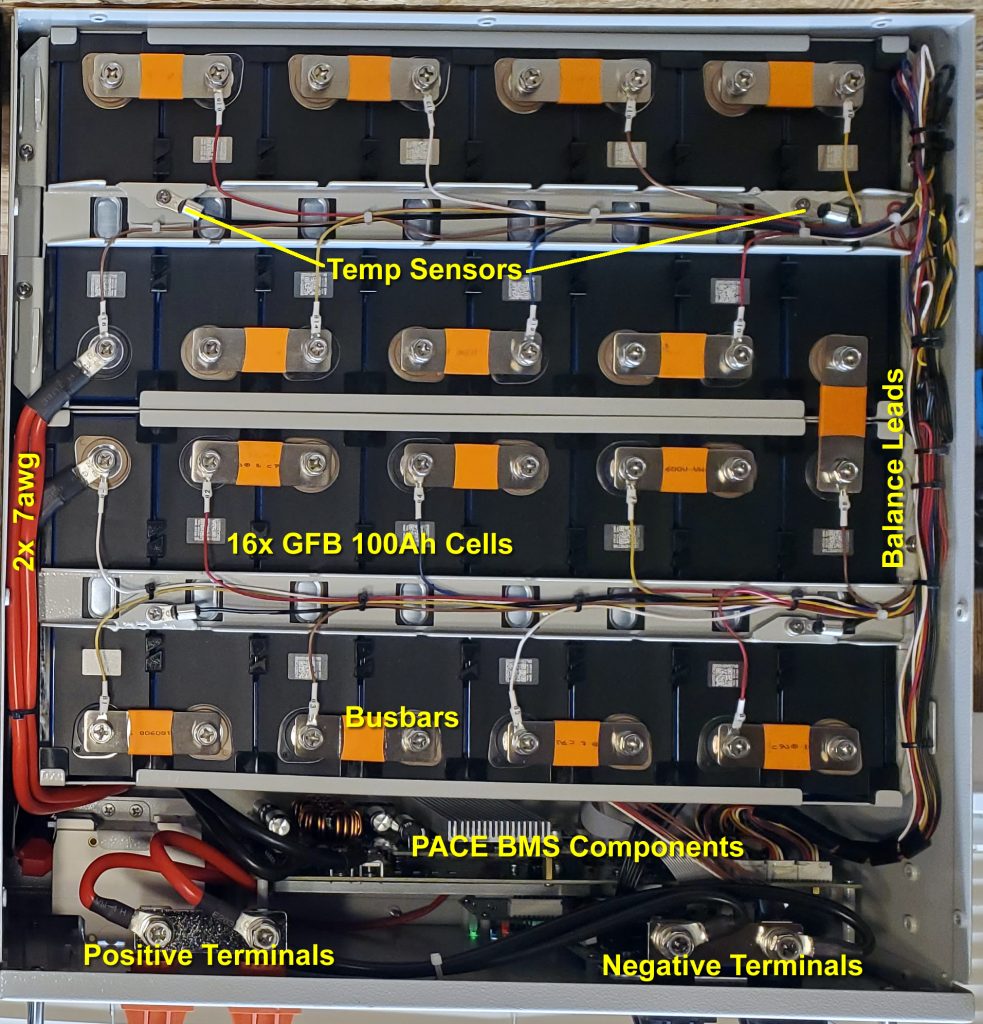

The internals of this battery are IMPRESSIVE. We have sixteen quality GFB 100Ah cells. They all appear flat without any sign of use or bloating. They’re separated by plastic spacers and each row is fixed in a removable steel cage to hold them in place and prohibit excess expansion. The busbars are made from multi-layer copper sheets giving it flexible properties should that ever be needed due to typical or abnormal cell expansion.

We have 4 temperature sensors located on the batteries – two on each row. The balance leads connect to each cell and are nicely run down the center of two support brackets. The wiring on the right-hand side is kindof a spaghetti mess; however, I’m told they are working on improving this. Lastly, the wiring exiting the main negative/positive poles of the battery on the left-hand side was done with a pair of 7awg for each negative and positive. They are silicone-insulated wires with a design temperature of 200C.

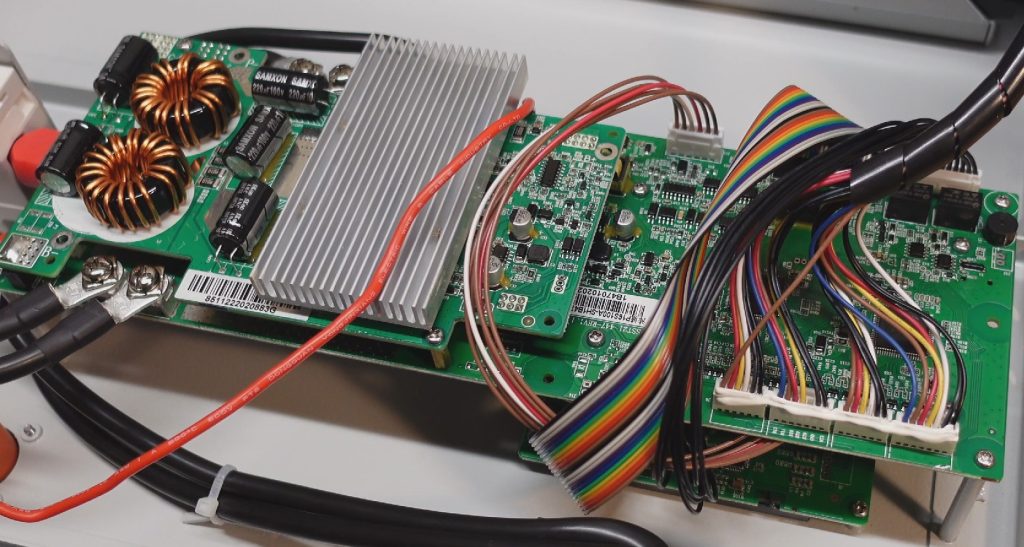

The BMS used is PACE-brand. The bulk of wires entering on the right-hand side are the balance leads. The ribbon cabling is feeding the display board and underlying communications ports. Additionally, we have a pair of inductors as this does have current limiting and a small pre-charge circuit for your inverter – very cool features.

That about concludes the blog writeup for this battery. For a more detailed review, please be sure to check the video below on Youtube. If you’re interested in learning more or purchasing one of the batteries, you can do that here. Thanks for reading!