The Vatrer 12V 7Ah LiFePO4 battery is perhaps one of the smallest batteries we have reviewed thus far. This review was a request from one of the commenters on our Youtube channel. I primarily deal with solar-related applications and thus don’t work with batteries this small; however, it was cheap – so why not. I ordered the battery from Amazon and it arrived the next day (really love Prime when it works).

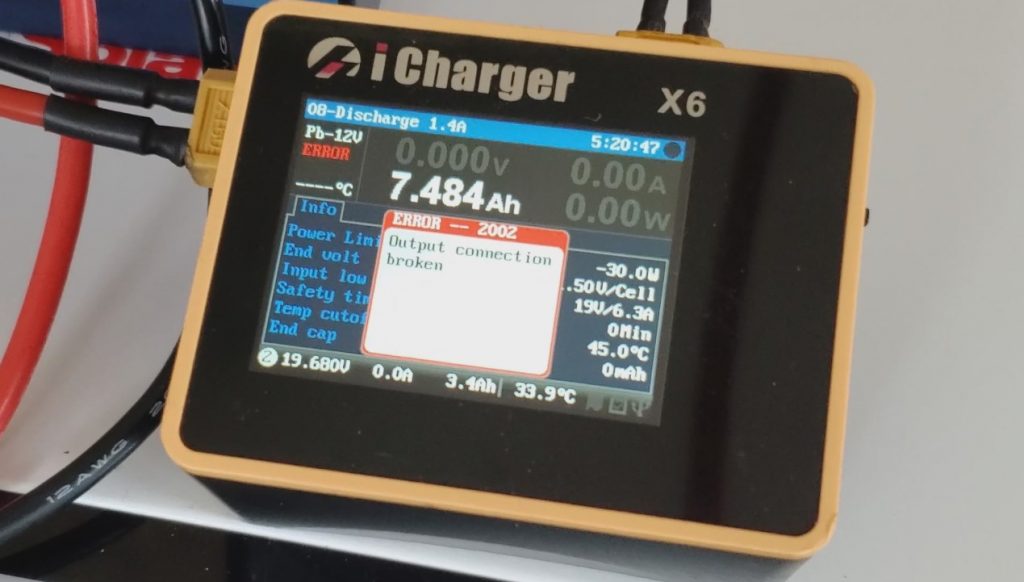

I spent most of the time focusing on the internals of the battery rather than its features as, with a battery this small, they’re fairly basic. It’s rated for a maximum charge and discharge current of 1C (which is a whopping 7A). I also ran a capacity test before tearing it apart. I tested using the iCharger x6 at a rate of 0.2C / 1.4A. The resulting capacity was 7.4Ah

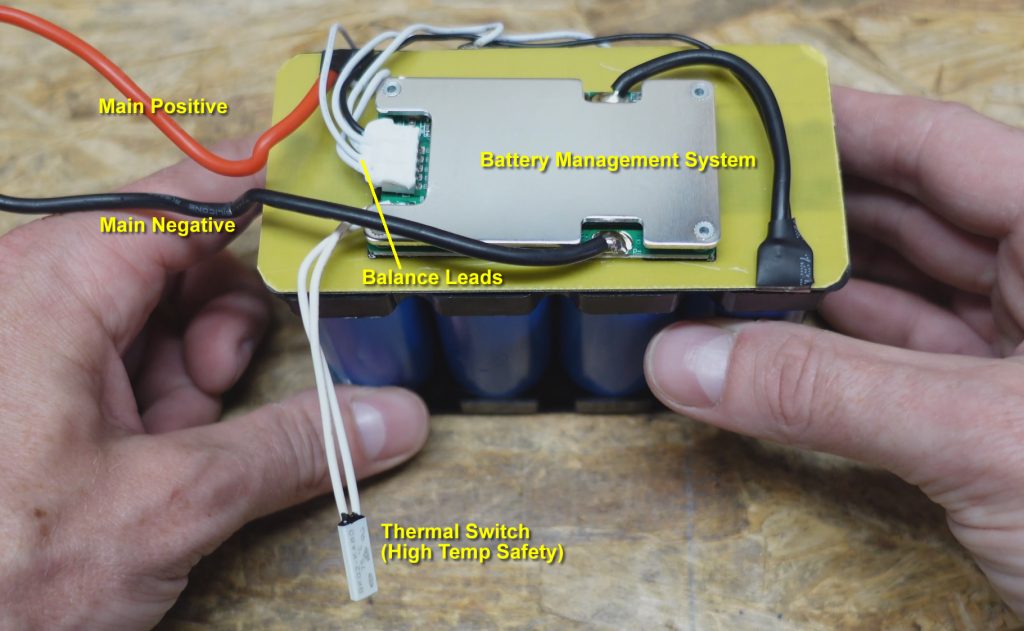

With the case open, we can see the battery pack nestled nicely inside. It’s wrapped with a layer of heat shrink and padded on all 4 sides with some hard foam-type material. Upon removing the pack and removing the heatshrink, we can see the BMS right on top. The BMS is separated from the battery pack with a layer of epoxy board. This is good for both insulative purposes and keeping heat generated by the BMS away from the battery cells.

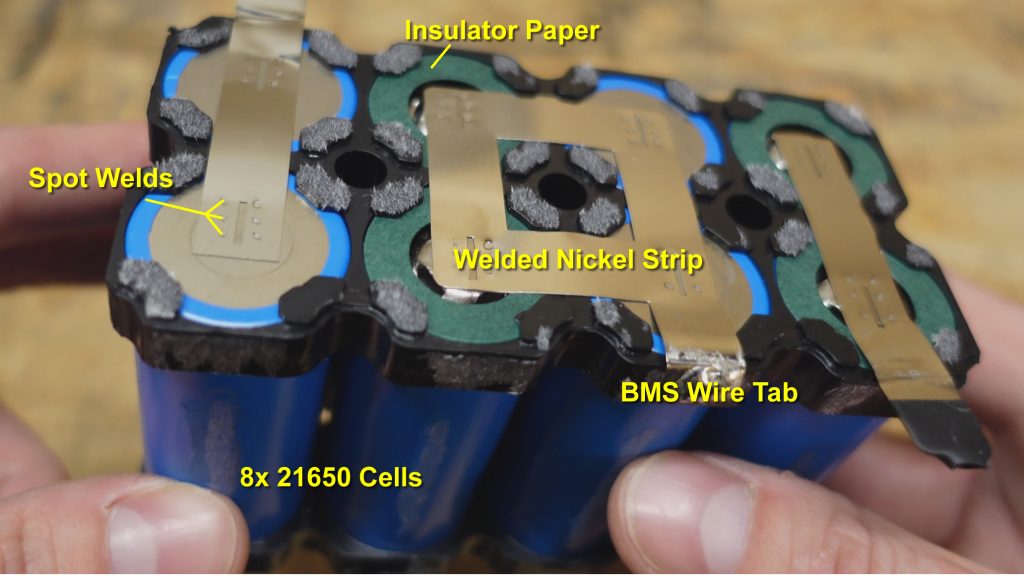

With the heat shrink removed from the battery pack, we can take a closer look at the cells and connection points. These are 26650 cells. That number contains 3 different components. The 26 means they’re 26mm in diameter, while 65 means they’re 65mm in length, and the 0 means they’re cylindrical. Unfortunately for us, there are no markings anywhere on the cell to determine the brand or model. Unlike aluminum-cased prismatic batteries, it’s much easier to fake these kinds of cells. For example, we don’t know if they were 4000mAh-rated cells before that didn’t test well and now they’re being sold as 3500mAh. To be clear, I’m not saying or suggesting that’s what is being done here, just that it’s something to watch out for.

Each cell was welded 3 times, creating 6 weld points. I like seeing that they used nickel strip with slots at the weld points. This helps create a better and more consistent weld. I also like that they used green insulator discs on the positive ends of the cells. This will help prevent the nickel from potentially rubbing through the thin layer of heat shrink and creating a short circuit. Extra safety is always good – right?

Overall, I like what I see here. I just wish we were able to identify the cell brand and model. For more information on this battery, please check the review and teardown video below.